Product

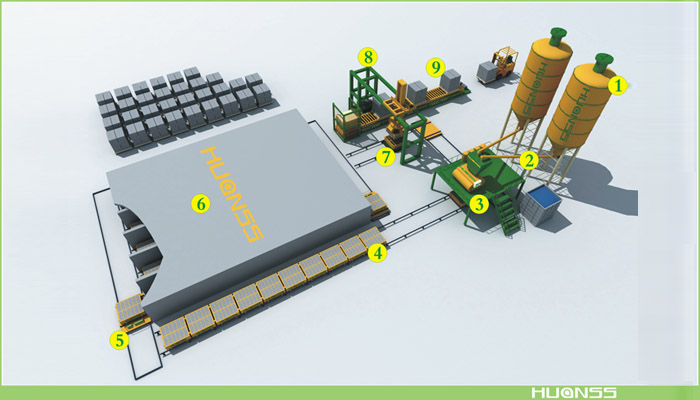

Simple Line of Foamed Concrete

Technical characteristics of cement foaming wall panel equipment:

1. Small investment and quick results.

2. The mode of production is flexible and easy to master. Fly ash cement foaming technology can produce not only light partition board, but also external wall insulation board and roof insulation board. It can be produced either by fixed production line or by mobile production.

3. Multi-purpose machine, large market coverage. In a production line, different products can be produced only by changing the mould.

4. Ultra-light thermal insulation products can be produced. Ultra-low density blocks of 200-300 kg/m3 can be produced. Such ultra-low density products can not be realized by other equipment and processes.

Huangshi concrete foaming production line, concrete foaming equipment has a shift capacity of 50 m3, 100 m3, 200 m3, 300 m3, 600 m3, 1000 m3 and other sizes, there are semi-manual, semi-automatic, automatic, full-automatic various grades, arbitrary choice. Among them, 1000m3 production line is the largest production line in China.

The production line of cement foamed brick has the following characteristics:

1. The original three-stage mixing pulping system, slurry uniformity is difficult to compare with the general mixer, can improve the strength and performance of products. Foamed cement brick machine

2. Invention of three-axle high-speed mixer, one minute can achieve the mixing effect of ordinary mixer for 5 minutes, shorten the forming cycle, improve the output, easily reach 300-1000m3 high output.

3, automatic mold cycle system maintenance and maintenance room automatic spray humidification maintenance, without carpenter and sprinkler maintenance, is currently the advanced maintenance system. Concrete foamed wallboard

4. Cutting system has not only single saw, but also semi-automatic, automatic and full-automatic cutting units such as three-sided cutting, five-sided cutting and six-sided cutting. All hanging billets and finished products are stacked by manipulators, and no one operates. It is a fully equipped cutting equipment at home and abroad. Foamed cement brick machine

5. The production line is equipped with automatic packaging machine and semi-automatic packaging machine, which realizes product packaging automation.

6. The feeding port of feeder and the feeding port of mixer are equipped with dust removal system. The effect of dust removal is over 96%. The cutting machine adopts dust-free cutting, and the production line achieves cleaner production.

7. Powder raw materials and liquid raw materials all realize automatic batching (small equipment is still artificial batching), accurate and fast batching, and save labor, can achieve unmanned batching.

8. Research and development of cutting waste activation treatment and reuse technology, no waste generation, zero emissions.

9. A set of equipment can be used for both physical foaming and chemical foaming, with one machine and two functions.

10. High degree of automation and complete matching. Fully automatic batching system, forming system, cycle maintenance system of die car, cutting system, packing and palletizing maintenance are all matched.

At present, our company's equipment is able to match five fully automated production lines.

1. Small investment and quick results.

2. The mode of production is flexible and easy to master. Fly ash cement foaming technology can produce not only light partition board, but also external wall insulation board and roof insulation board. It can be produced either by fixed production line or by mobile production.

3. Multi-purpose machine, large market coverage. In a production line, different products can be produced only by changing the mould.

4. Ultra-light thermal insulation products can be produced. Ultra-low density blocks of 200-300 kg/m3 can be produced. Such ultra-low density products can not be realized by other equipment and processes.

Huangshi concrete foaming production line, concrete foaming equipment has a shift capacity of 50 m3, 100 m3, 200 m3, 300 m3, 600 m3, 1000 m3 and other sizes, there are semi-manual, semi-automatic, automatic, full-automatic various grades, arbitrary choice. Among them, 1000m3 production line is the largest production line in China.

The production line of cement foamed brick has the following characteristics:

1. The original three-stage mixing pulping system, slurry uniformity is difficult to compare with the general mixer, can improve the strength and performance of products. Foamed cement brick machine

2. Invention of three-axle high-speed mixer, one minute can achieve the mixing effect of ordinary mixer for 5 minutes, shorten the forming cycle, improve the output, easily reach 300-1000m3 high output.

3, automatic mold cycle system maintenance and maintenance room automatic spray humidification maintenance, without carpenter and sprinkler maintenance, is currently the advanced maintenance system. Concrete foamed wallboard

4. Cutting system has not only single saw, but also semi-automatic, automatic and full-automatic cutting units such as three-sided cutting, five-sided cutting and six-sided cutting. All hanging billets and finished products are stacked by manipulators, and no one operates. It is a fully equipped cutting equipment at home and abroad. Foamed cement brick machine

5. The production line is equipped with automatic packaging machine and semi-automatic packaging machine, which realizes product packaging automation.

6. The feeding port of feeder and the feeding port of mixer are equipped with dust removal system. The effect of dust removal is over 96%. The cutting machine adopts dust-free cutting, and the production line achieves cleaner production.

7. Powder raw materials and liquid raw materials all realize automatic batching (small equipment is still artificial batching), accurate and fast batching, and save labor, can achieve unmanned batching.

8. Research and development of cutting waste activation treatment and reuse technology, no waste generation, zero emissions.

9. A set of equipment can be used for both physical foaming and chemical foaming, with one machine and two functions.

10. High degree of automation and complete matching. Fully automatic batching system, forming system, cycle maintenance system of die car, cutting system, packing and palletizing maintenance are all matched.

At present, our company's equipment is able to match five fully automated production lines.