Product

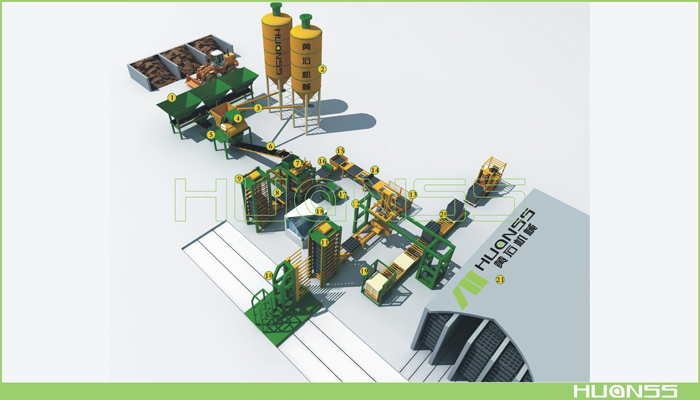

Automatic Brick Production Line

1. batching bin 2. cement bin / fly ash bin 3. screw conveyor

4. Cement Scale 5. Mixer 6. Conveyor Belt

7. Forming Main Machine 8. Brick Putting Machine 9. Lifting Machine

10. Mother and child car 11. Plate descending machine 12. Brick yard machine

13. Flipping Machine 14, Pallet Return Machine 15, Pallet Warehouse

16. Pallet dipper 17, pallet dipper 18, central control room

19. Pallet Warehouse 20, Product Conveyor 21, Steam Maintenance Kiln

4. Cement Scale 5. Mixer 6. Conveyor Belt

7. Forming Main Machine 8. Brick Putting Machine 9. Lifting Machine

10. Mother and child car 11. Plate descending machine 12. Brick yard machine

13. Flipping Machine 14, Pallet Return Machine 15, Pallet Warehouse

16. Pallet dipper 17, pallet dipper 18, central control room

19. Pallet Warehouse 20, Product Conveyor 21, Steam Maintenance Kiln

The automatic pipeline is maintained by steam for 16 hours. The finished product can be maintained 25 days ahead of schedule. The block can be supplied to the market in one week.

Raw material storage area: 1200 square meters

Brick machine assembly line: 260 square meters (13 meters*20 meters)

Steam curing kiln: 220 square meters (13m*17m)